news

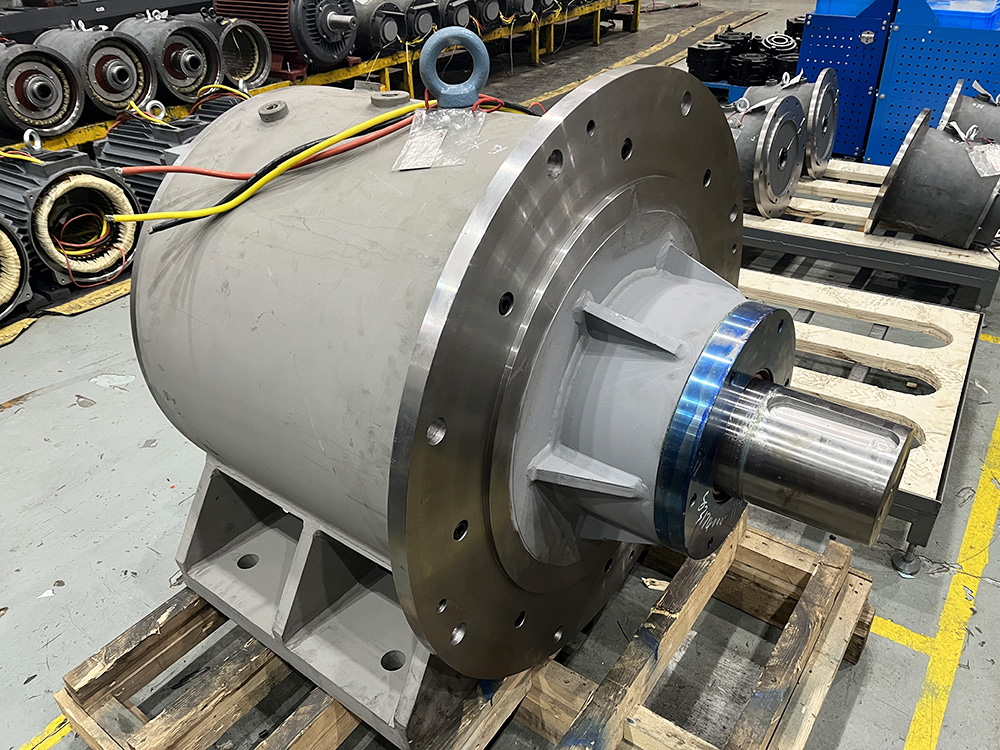

how to ensure the reliability of servo permanent magnet direct drive motors?

2024-07-05 09:35:01来源:

the reliability of servo permanent magnet direct drive motors is mainly reflected in their design, manufacturing, material selection, and operation and maintenance. these motors use high-quality permanent magnet materials and precise manufacturing processes to ensure the stability and durability of their core components. in addition, the servo permanent magnet direct drive motor also has intelligent monitoring and maintenance functions, which can monitor the operating status in real time, detect and handle potential faults in a timely manner, thereby reducing the failure rate and downtime.

the following are several key points to ensure the reliability of servo permanent magnet direct drive motors:

1. material selection and quality control:

·select high-quality permanent magnet materials, such as neodymium iron boron (ndfeb), to ensure that the permanent magnet can maintain stable magnetic properties in high temperature and high magnetic field environments.

·strictly control the quality of all motor components, including material composition, dimensional accuracy, surface treatment, etc., to ensure the durability and reliability of the components.

2. advanced design and simulation:

·using advanced electromagnetic and thermal design techniques, the performance and behavior of the motor are predicted through simulation analysis to ensure that the design meets reliability requirements.

·consider factors such as vibration, noise, and temperature rise of the motor, and optimize the design to reduce the impact of these factors on the reliability of the motor.

3. precision manufacturing process:

·using precision manufacturing equipment and processes to ensure the machining accuracy and assembly quality of various components of the motor.

·implement strict quality inspection and testing processes to ensure that each motor meets quality standards before leaving the factory.

4. thermal management and cooling design:

·design an effective heat dissipation system to ensure that the heat generated by the motor during operation can be dissipated in a timely manner, avoiding performance degradation or damage caused by overheating.

·choose appropriate cooling methods (such as natural cooling, forced air cooling, water cooling, etc.) based on the specific needs and application environment of the motor.

5. reliable bearings and seals:

·select high-quality bearings to ensure stable operation of the motor during high-speed rotation and reduce downtime caused by bearing failures.

·strengthen the sealing design of the motor to prevent impurities such as dust and moisture from entering the interior of the motor, which can affect its performance and lifespan.

6. intelligent monitoring and maintenance:

·integrate intelligent sensors and monitoring systems to monitor the operating status and parameters of the motor in real time (such as temperature, vibration, current, etc.), timely detect potential faults and give early warnings.

·provide regular maintenance and guidance to ensure proper maintenance and upkeep of the motor during use, and extend its service life.

7. strict testing and verification:

·strict testing and validation, including performance testing, reliability testing, and environmental adaptability testing, are carried out in the research and production process of motors to ensure that they can operate reliably under various working conditions.

·perform statistical analysis on test results, continuously optimize design and manufacturing processes, and improve the reliability and stability of the motor.

in summary, measures such as material selection and quality control, advanced design and simulation, precise manufacturing processes, thermal management and heat dissipation design, reliable bearings and seals, intelligent monitoring and maintenance, and strict testing and verification can effectively ensure the reliability of servo permanent magnet direct drive motors.

hengda electric has always been dedicated to the research and development, production, and service of permanent magnet direct drive motors. with advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, the company provides customers with the most suitable professional motor solutions and creates greater social value.